Internal Gear

Internal gears are a type of gear system that is designed with teeth on the inside of thegear, rather than on the outside. These gears are often used in mechanical powertransmissions to achieve high gear reduction ratios and transmit torque in a compactspace. In this blog post, we will explore the benefits and applications of internal gears.

Advantages of Internal Gears

Applications of Internal Gears

Conclusion

Internal gears are a versatile and reliable type of gear system that can achieve high gearreduction ratios and transmit torque in a compact space. These features make themsuitable for a wide range of applications, including wind turbines, robotics, printingpresses, and industrial machinery. With their smooth operation, high load capacity, andreliable performance, internal gears are an essential component of many mechanicalsystems.

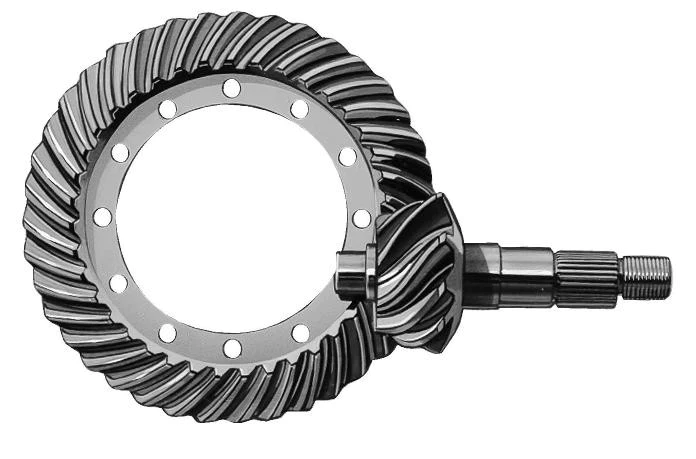

Hypoid Gears

Hypoid gears are a type of gear used to transfer rotational motion between two intersecting shafts that are not parallel. They have a unique tooth profile that combinesthe features of spiral bevel gears and worm gears, making them suitable for a widerange of applications. In this blog post, we will explore the advantages and applicationsof hypoid gears.

Advantages of Hypoid Gears

Applications of Hypoid Gears

Conclusion

Hypoid gears are a versatile and efficient type of gear system that is essential fortransferring power between two intersecting shafts that are not parallel. With their highefficiency, quiet operation, and increased torque, hypoid gears are suitable for a widerange of applications, including automotive, industrial, aerospace, and roboticsindustries. Hypoid gears are an excellent choice for applications where high torque andsmooth operation are required.

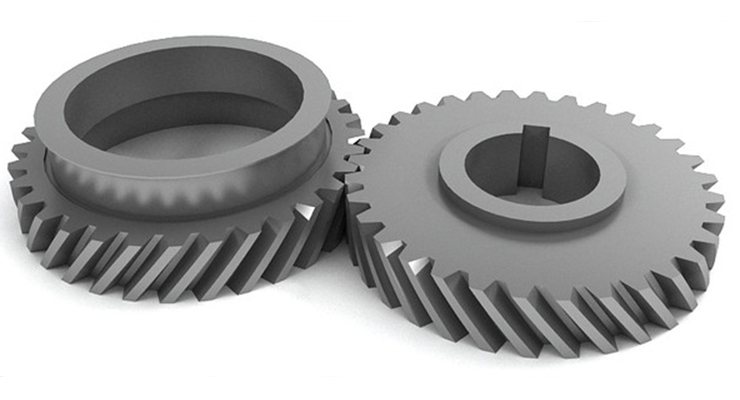

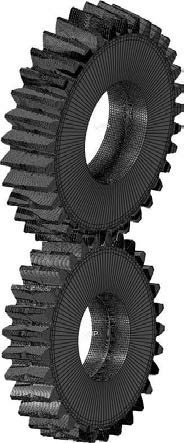

Herringbone Gear

Herringbone gears, also known as double helical gears, are a type of gear commonlyused in heavy-duty industrial applications. They are characterized by their unique V-shaped teeth that allow for greater load carrying capacity and smoother operation thantraditional spur gears.

How Do Herringbone Gears Work?

Herringbone gears consist of two helical gears that are mounted adjacent to each otherwith opposing helix angles. This design creates a V-shaped tooth profile that eliminatesthe axial thrust generated by traditional helical gears. As a result, herringbone gears can handle greater loads and operate more smoothly and quietly than their helicalcounterparts.

Advantages of Herringbone Gears

Applications of Herringbone Gears

Herringbone gears are commonly used in heavy-duty industrial applications, such as:

Conclusion

Herringbone gears are a critical component of many heavy-duty industrial applicationsthat require high torque and load carrying capacity. Their unique V-shaped toothprofile and opposing helix angles provide several advantages over traditional spur orhelical gears, including greater load capacity, smoother operation, increased efficiency, and better heat dissipation. With their broad range of applications and benefits, herringbone gears are an essential component of many mechanical systems that requireprecise and reliable power transmission.

Helical Gear

Helical gears are a type of gear that is widely used in mechanical power transmissionsystems. They are characterized by their unique tooth geometry, which is helical ortwisted in shape. This design provides several advantages over other types of gears, including increased load capacity, smoother operation, and reduced noise and vibration.

How Do Helical Gears Work?

Helical gears work by transferring rotational power from one shaft to another through a series of interlocking teeth. The teeth on a helical gear are cut at an angle to the gear’saxis, resulting in a twisted or helical shape. When two helical gears are meshed together, the helical teeth form a diagonal contact pattern, which spreads the load across a largersurface area than other types of gears.

Advantages of Helical Gears

Applications of Helical Gears

Helical gears are used in a wide range of applications, including:

Conclusion

Helical gears are a versatile and reliable type of gear that is widely used in mechanicalpower transmission systems. Their unique tooth geometry provides several advantagesover other types of gears, including increased load capacity, smoother operation, andreduced noise and vibration. With their broad range of applications and benefits, helicalgears are a critical component of many mechanical systems.

Ground Gear

Ground gears are a type of gear that is produced by grinding instead of cutting. Thisgrinding process creates a more precise and consistent gear than traditional cuttingmethods. In this blog post, we will explore the advantages and applications of groundgears.

Advantages of Ground Gears

Applications of Ground Gears

Conclusion

Ground gears are a high-precision and high-strength gear system that is ideal for a widerange of applications. With their precise tooth profile, smooth operation, high strength, and reduced friction, ground gears are a reliable and efficient choice for aerospace, automotive, industrial, and robotics applications. Ground gears provide the necessaryprecision and durability for critical applications that require precise motion control andhigh load capacity.

Crowned Gear

Crowned gears are specialized gears that are used in applications where misalignmentbetween the driving and driven shafts is likely to occur. They are commonly used in equipment such as conveyors, printing presses, and packaging machinery, where precisealignment is crucial for optimal performance.

What are Crowned Gears?

Crowned gears are gears that have a specially designed tooth profile that is slightlycurved or tapered towards the center of the gear. This design allows the gear toaccommodate small misalignments between the driving and driven shafts while stillmaintaining constant contact between the teeth of the gears. The slight curve or taper of the tooth profile ensures that the gears only touch at their highest point, which reduceswear and tear on the gear teeth and extends their lifespan.

Applications of Crowned Gears

Crowned gears are commonly used in applications where precise alignment is difficult toachieve or maintain. They are particularly useful in equipment that is subject to changesin temperature, vibration, or other environmental factors that can cause misalignmentbetween the driving and driven shafts.

Some of the common applications of crowned gears include:

Benefits of Crowned Gears

The benefits of using crowned gears in equipment are numerous. Some of the keybenefits include:

In conclusion, crowned gears are a specialized type of gear that is designed toaccommodate misalignment between the driving and driven shafts. They are commonlyused in a wide range of industrial applications and can help to improve equipmentperformance, increase lifespan, and reduce downtime. By understanding the benefits of crowned gears, equipment operators can select the right type of gear for their specificapplication and ensure optimal performance and reliability.

Bevel Oid Gear

Bevel oid gears are a type of bevel gear that have curved teeth rather than straight teeth. This unique design allows for smoother, quieter operation and improved load carrying capacity compared to traditional straight-tooth bevel gears. Beveloid gears are widelyused in a variety of applications, including automotive, aerospace, and industrialmachinery.

How Do Bevel oid Gears Work?

Bevel oid gears are designed to transmit rotational power between two intersecting shaftsthat are not parallel to one another. The teeth of a beveloid gear are cut at an angle tothe axis of the gear, which allows the gear to mesh with another beveloid gear or a straight-tooth bevel gear. Beveloid gears can be either external or internal, dependingon whether the teeth are located on the outer or inner surface of the gear.

Advantages of Bevel oid Gears

Applications of Bevel oid Gears

Beveloid gears are used in a wide range of applications, including:

Conclusion

Bevel oid gears are a critical component of many mechanical power transmissionsystems. Their unique design provides several advantages over traditional straight-toothbevel gears, including improved load carrying capacity, reduced noise and vibration, greater design flexibility, and improved efficiency. With their broad range of applications and benefits, beveloid gears are an essential component of manymechanical systems that require precise and reliable power transmission.