List of Ten Different Types of Industrial Gearboxes

Here are ten different types of industrial gearboxes:

1.Helical Gearbox: This type of gearbox has helical gears, which have teeth thatare cut at an angle to the gear axis. Helical gearboxes are known for their smooth andquiet operation, and they are commonly used in conveyor systems, cranes, and mixers.

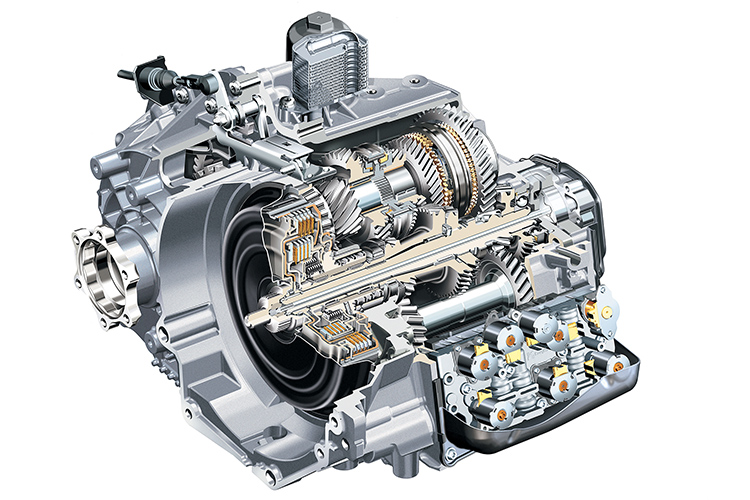

2.Planetary Gearbox: This type of gearbox has a central sun gear, planet gears, and a ring gear. Planetary gearboxes are known for their high torque and compactdesign, and they are commonly used in industrial machinery, robotics, and automotiveapplications.

3.Worm Gearbox: This type of gearbox has a worm gear that meshes with a spurgear. Worm gearboxes are known for their high reduction ratio, making them useful in applications that require slow speeds and high torque, such as winches, hoists, andconveyors.

4.Bevel Gearbox: This type of gearbox has bevel gears that are used to transmit power between shafts that are not parallel. Bevel gearboxes are commonly used in industrial applications that require high speed and efficiency, such as pumps, compressors, and turbines.

5.Cycloidal Gearbox: This type of gearbox uses a set of cycloidal disks to transmit power between shafts. Cycloidal gearboxes are known for their high torque and lowbacklash, and they are commonly used in industrial machinery, robotics, andautomation applications.

6.Parallel Shaft Gearbox: This type of gearbox has parallel shafts that transmit power between gears. Parallel shaft gearboxes are commonly used in industrialapplications that require high power transmission, such as steel mills and miningequipment.

7.Offset Shaft Gearbox: This type of gearbox has offset shafts that transmit power between gears. Offset shaft gearboxes are commonly used in industrialapplications that require precise positioning, such as printing presses and packagingmachinery.

8.Right-Angle Gearbox: This type of gearbox has right-angle gears that transmit power between shafts that are perpendicular to each other. Right-angle gearboxes arecommonly used in industrial applications that require compact design and high torque, such as machine tools and robotics.

9.Hypoid Gearbox: This type of gearbox has hypoid gears that are designed totransmit power between non-intersecting shafts. Hypoid gearboxes are commonly usedin automotive applications, such as differential gears.

10.Harmonic Drive Gearbox: This type of gearbox uses a set of flexspline, wavegenerator, and circular spline to transmit power with high precision and low backlash. Harmonic drive gearboxes are commonly used in industrial robots, semiconductorequipment, and aerospace applications.