Gearbox Manufacturing Processes: From Design to Production

Gearboxes are critical components used in various industries, including automotive, aerospace, machinery, and robotics. They play a vital role in power transmission and motion control. The manufacturing of gearboxes requires a systematic approach to ensure precision, durability, and reliable performance. In this blog post, we will explore the key steps involved in gearbox manufacturing processes, from design to production.

Gearbox Design:

The first step in gearbox manufacturing is the design phase. Gearbox designers utilize computer-aided design (CAD) software to create detailed 3D models of the gearbox components, including the housing, shafts, bearings, and gears. The design process involves determining the gear ratio, torque requirements, input and output speeds, and the overall size and configuration of the gearbox.

Material Selection:

Selecting the appropriate materials for gearbox components is crucial for strength, durability, and performance. Common materials used for gearbox manufacturing include alloy steels, cast iron, aluminum alloys, and various engineering plastics. The material selection is based on factors such as load capacity, operating conditions, temperature, and cost considerations.

Machining and Fabrication:

After the gearbox design is finalized, the manufacturing process begins with machining and fabrication of the gearbox components. This involves processes such as milling, turning, drilling, and grinding to shape the gearbox housing, shafts, and other parts. CNC (Computer Numerical Control) machines are often used to ensure accuracy and consistency in the manufacturing process.

Gear Cutting:

Gear cutting is a critical step in gearbox manufacturing. It involves the production of gears with the desired tooth profiles and specifications. Gear cutting methods such as hobbing, shaping, milling, or broaching are employed to create the gears. The gear cutting process ensures proper gear meshing and efficient power transmission within the gearbox.

Assembly and Fitting:

Once the gearbox components, including the housing, shafts, bearings, and gears, are manufactured, they are assembled and fitted together. This involves precise alignment and fitting of the components to ensure smooth operation and accurate gear meshing. Lubrication systems and seals are also installed during the assembly process to provide proper lubrication and prevent contamination.

Testing and Quality Control:

Gearboxes undergo rigorous testing and quality control measures to ensure their performance and reliability. Functional tests, such as load testing, vibration testing, and endurance testing, are conducted to verify the gearbox’s ability to handle the specified loads and operating conditions. Additionally, quality control inspections, including dimensional checks and surface finish evaluations, are performed to ensure adherence to design specifications and standards.

Final Finishing and Packaging:

After testing and quality control, the gearbox undergoes any required final finishing operations, such as deburring or surface treatment, to improve its appearance and functionality. The gearbox is then properly packaged, ensuring protection during transportation and storage until it reaches the end-user or assembly line.

Gearbox manufacturing is a complex process that requires precision and attention to detail. From gearbox design and material selection to machining, gear cutting, assembly, testing, and final finishing, each step plays a vital role in producing a high-quality and reliable gearbox. By following stringent manufacturing processes and adhering to quality control measures, gearbox manufacturers can deliver products that meet the performance requirements and specifications of various industries.

Gear Manufacturing Processes: From Design to Production

Gears are essential components used in various industries, from automotive and aerospace to machinery and robotics. The manufacturing of gears requires a precise and systematic approach to ensure optimal performance, durability, and reliability. In this blog post, we will explore the key steps involved in gear manufacturing processes, from design to production.

Gear Design:

The first step in gear manufacturing is the design phase. Gear designers utilize specialized software and tools to create the gear geometry, taking into account factors such as tooth profile, module, pressure angle, and pitch diameter. The design process also involves considering the specific application requirements, load capacity, and desired performance characteristics of the gear.

Material Selection:

Choosing the right material for gear production is crucial to ensure strength, wear resistance, and durability. Commonly used materials for gears include alloy steels, stainless steels, and non-ferrous metals like bronze and brass. The material selection is based on factors such as load capacity, operating conditions, and cost considerations.

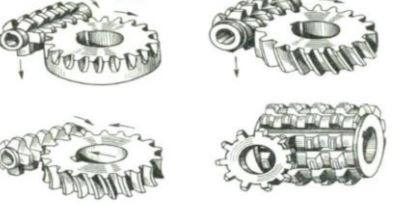

Gear Cutting:

Gear cutting is a critical process in gear manufacturing. It involves removing material from a gear blank to create the desired tooth profile. There are several methods for gear cutting, including hobbing, shaping, milling, and broaching. Each method has its advantages and is chosen based on factors such as gear type, volume, and accuracy requirements.

Heat Treatment:

After gear cutting, the gears often undergo heat treatment processes to enhance their mechanical properties. Heat treatment techniques such as carburizing, quenching, and tempering are employed to achieve desired hardness, toughness, and wear resistance. Heat treatment ensures that the gears can withstand the stresses and loads they will encounter during operation.

Finishing Operations:

Once the gears have undergone heat treatment, they go through various finishing operations. These include grinding, honing, lapping, and deburring to achieve the desired surface finish, dimensional accuracy, and tooth profile quality. Finishing operations are essential for reducing noise, improving gear meshing, and ensuring smooth and efficient operation.

Inspection and Quality Control:

Throughout the manufacturing process, gears undergo rigorous inspection and quality control measures. This involves using precision measurement tools and equipment to check dimensional accuracy, tooth profile, surface finish, and hardness. Advanced inspection techniques such as coordinate measuring machines (CMMs) and non-destructive testing methods are employed to ensure the gears meet the required specifications and standards.

Assembly and Testing:

In some applications, gears are assembled into gearboxes or transmission systems. This involves carefully aligning the gears, shafts, and bearings to ensure proper gear meshing and smooth operation. Gear assemblies are then subjected to functional testing, including load testing, noise testing, and endurance testing, to verify their performance under real-world conditions.

Gear manufacturing is a complex and precise process that involves multiple steps, from gear design to production. Each step, from gear cutting and heat treatment to finishing operations and quality control, is crucial in ensuring the final gears meet the required specifications and performance standards. By following a systematic approach and employing advanced manufacturing techniques, gear manufacturers can produce high-quality gears that provide reliable and efficient performance in various applications.

Couplings and Backstops Manufacturing Processes: Ensuring Efficient Power Transmission

Couplings and backstops are essential components used in various industries for efficient power transmission and motion control. They play a crucial role in connecting rotating shafts, absorbing misalignment, and preventing reverse rotation. The manufacturing of couplings and backstops involves precise processes to ensure durability, reliability, and optimal performance. In this blog post, we will explore the key steps involved in couplings and backstops manufacturing processes.

1. Design and Engineering: The manufacturing process begins with the design and engineering phase. Coupling and backstop designers utilize CAD software and advanced engineering principles to create detailed designs. The design process involves considering factors such as torque capacity, misalignment compensation, operating conditions, and specific industry requirements.

2. Material Selection: Choosing the right materials for couplings and backstops is crucial to ensure strength, durability, and performance. Common materials used for manufacturing include alloy steels, stainless steels, and various engineering plastics. The material selection is based on factors such as torque capacity, operating conditions (including temperature and corrosive environments), and cost considerations.

3. Machining and Fabrication: Once the design is finalized, the manufacturing process begins with machining and fabrication. This involves shaping and forming the coupling or backstop components through processes such as milling, turning, drilling, and grinding. CNC machines are often used to ensure precision and consistency in the manufacturing process.

4. Heat Treatment and Surface Treatment: Couplings and backstops often undergo heat treatment processes to enhance their mechanical properties. Heat treatment techniques such as quenching and tempering are employed to achieve the desired hardness, toughness, and wear resistance. Surface treatment methods such as coating or plating may also be applied to provide additional protection against corrosion and wear.

5. Assembly and Balancing: Once the individual components are manufactured and treated, they are assembled to create the complete coupling or backstop mechanism. Assembly involves precise fitting and alignment of the components to ensure smooth operation and optimal performance. Balancing is also performed to minimize vibration and ensure stable operation at high rotational speeds.

6. Testing and Quality Control: Couplings and backstops undergo rigorous testing and quality control measures to ensure their performance and reliability. Functional tests, including torque testing, misalignment testing, and endurance testing, are conducted to verify the components’ ability to handle specified loads and operating conditions. Quality control inspections, including dimensional checks and surface finish evaluations, are performed to ensure adherence to design specifications and standards.

7. Packaging and Delivery: After testing and quality control, the couplings and backstops are properly packaged to ensure protection during transportation and storage. Packaging materials and methods are chosen to safeguard the components and prevent any damage during handling and shipping. The products are then delivered to the customers or integrated into larger systems or machinery.

The manufacturing of couplings and backstops involves a series of precise processes to ensure durability, reliability, and efficient power transmission. From design and material selection to machining, heat treatment, assembly, and quality control, each step plays a vital role in producing high-quality components. By following stringent manufacturing processes and adhering to quality control measures, manufacturers can deliver couplings and backstops that meet the performance requirements and specifications of various industries.