Reducer Conveyor Belts

In many industrial applications, conveyor belts play a crucial role in the efficient andsafe transportation of materials. However, conveyor belts can operate at high speeds, making it challenging to control the flow of materials in some cases. That’s wherereducer conveyor belts come in. In this blog post, we’ll explore the features and benefitsof reducer conveyor belts.

Features of Reducer Conveyor Belts

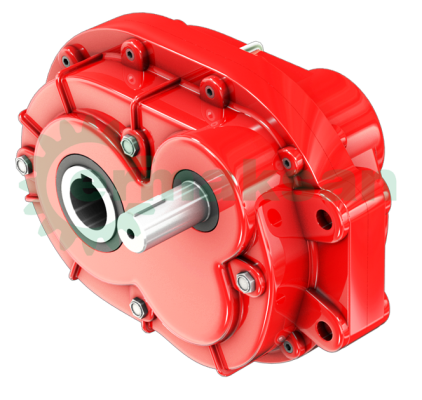

A reducer conveyor belt is designed with a specialized gearbox that reduces the speed of the conveyor belt while maintaining the same torque. The gearbox is typically mounteddirectly onto the drive pulley of the conveyor belt and works by converting the high-speed rotational motion of the motor or engine into a lower speed but higher torqueoutput.

The reducer conveyor belt consists of a series of gears and bearings that are designed towithstand high loads and work efficiently in harsh environments. The gears are typicallymade of high-strength materials such as hardened steel or cast iron to handle the hightorque loads generated by the conveyor belt.

Benefits of Reducer Conveyor Belts

There are several benefits to using a reducer conveyor belt in industrial applications. Some of these benefits include:

Conclusion

In conclusion, reducer conveyor belts play an important role in many industrialapplications by improving the safety, efficiency, and control of conveyor systems. Theirability to reduce the speed of the conveyor belt while maintaining the same torqueoutput provides many benefits, including increased safety, improved efficiency, bettercontrol, longer belt life, and customizability. If you’re looking to improve your conveyorsystem’s performance, a reducer conveyor belt may be the solution you need.