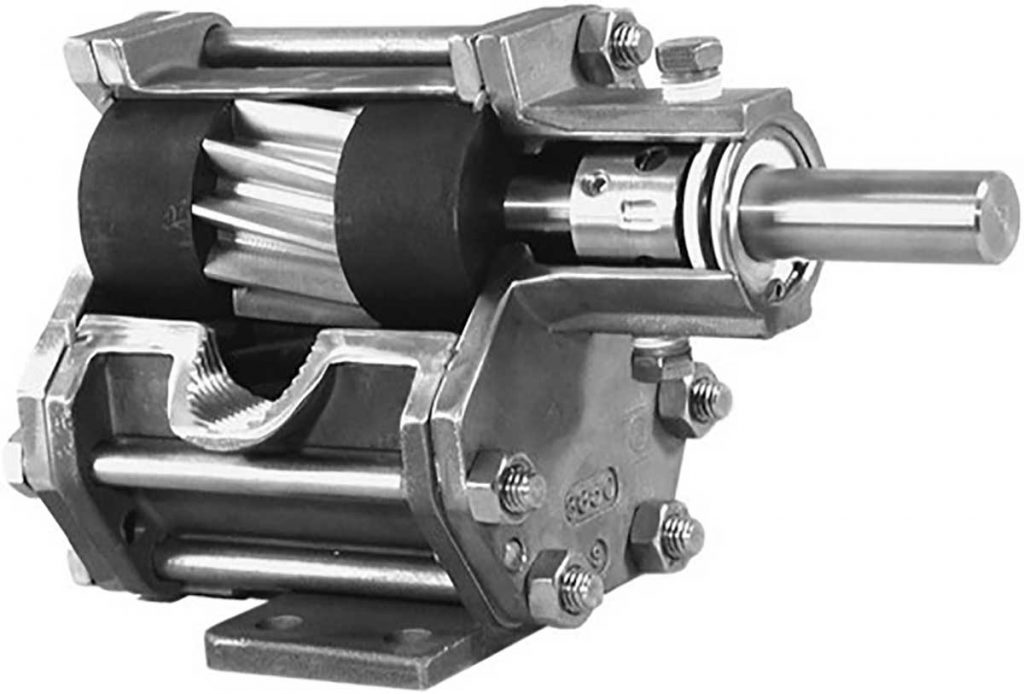

Pump Gear

Pump gear refers to the gear set used in positive displacement pumps to transfer fluidsfrom one location to another. These gear sets are essential components in manyindustries, including oil and gas, chemical processing, and food and beverage. In thisblog post, we will take a closer look at pump gear, its functions, types, and benefits.

Functions of Pump Gear

The primary function of pump gear is to transfer fluids from one location to another in a positive displacement pump. Positive displacement pumps work by trapping a fixedamount of fluid between the gears and the pump housing, and then transferring thatfluid from the inlet to the outlet. Pump gear plays a critical role in this process, ensuringthat the fluid is transferred efficiently and effectively.

Types of Pump Gear

There are several different types of pump gear available on the market, each designedfor specific applications and operating conditions. Some of the most common types of pump gear include:

Benefits of Pump Gear

Pump gear offers several benefits over other types of pump components. Some of themost significant benefits of pump gear include:

In conclusion, pump gear is an essential component in many industrial applications. It is designed to transfer fluids from one location to another efficiently and effectively, making it critical to the operation of positive displacement pumps. By understanding thefunctions, types, and benefits of pump gear, users can select the right type of gear fortheir specific application, ensuring maximum performance and efficiency.