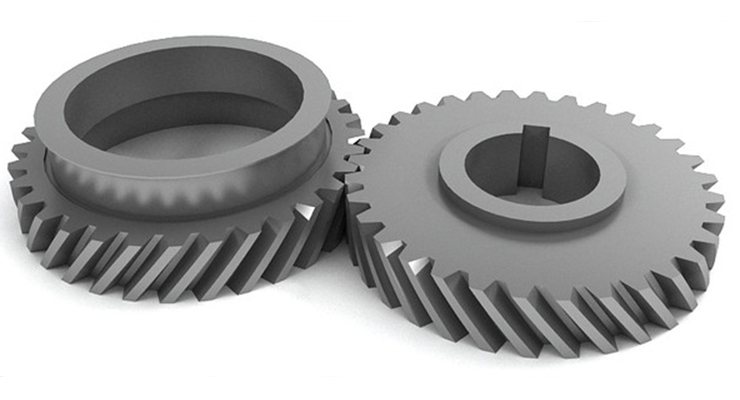

Helical gears are a type of gear that is widely used in mechanical power transmissionsystems. They are characterized by their unique tooth geometry, which is helical ortwisted in shape. This design provides several advantages over other types of gears, including increased load capacity, smoother operation, and reduced noise and vibration.

How Do Helical Gears Work?

Helical gears work by transferring rotational power from one shaft to another through a series of interlocking teeth. The teeth on a helical gear are cut at an angle to the gear’saxis, resulting in a twisted or helical shape. When two helical gears are meshed together, the helical teeth form a diagonal contact pattern, which spreads the load across a largersurface area than other types of gears.

Advantages of Helical Gears

1. Increased Load Capacity: Helical gears have a greater load-carrying capacity thanother types of gears due to their larger contact area. This allows them to transmit higher torque and power loads, making them ideal for heavy-duty applications.

2. Smoother Operation: The helical tooth geometry of helical gears results in a smooth and gradual transfer of power, reducing shock loads and minimizingnoise and vibration.

3. Higher Efficiency: Helical gears have a higher efficiency than other types of gearsdue to their diagonal contact pattern, which minimizes friction and power loss.

4. Greater Precision: The helical tooth geometry of helical gears allows for greaterprecision in gear placement and alignment, resulting in more accurate andconsistent operation.

Applications of Helical Gears

Helical gears are used in a wide range of applications, including:

1. Automotive transmissions: Helical gears are commonly used in automotivetransmissions, where they provide smooth and efficient power transfer.

2. Industrial machinery: Helical gears are used in a variety of industrial machinery, including pumps, compressors, and conveyors.

3. Robotics: Helical gears are used in robotics applications, where their smoothoperation and high load-carrying capacity are critical for precise and reliablemovement.

4. Aerospace: Helical gears are used in aircraft engines and other aerospaceapplications, where their high efficiency and reliability are essential for safe andefficient operation.

Conclusion

Helical gears are a versatile and reliable type of gear that is widely used in mechanicalpower transmission systems. Their unique tooth geometry provides several advantagesover other types of gears, including increased load capacity, smoother operation, andreduced noise and vibration. With their broad range of applications and benefits, helicalgears are a critical component of many mechanical systems.