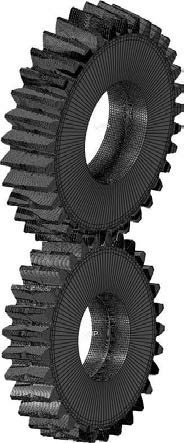

Bevel Oid Gear

Bevel oid gears are a type of bevel gear that have curved teeth rather than straight teeth. This unique design allows for smoother, quieter operation and improved load carrying capacity compared to traditional straight-tooth bevel gears. Beveloid gears are widelyused in a variety of applications, including automotive, aerospace, and industrialmachinery.

How Do Bevel oid Gears Work?

Bevel oid gears are designed to transmit rotational power between two intersecting shaftsthat are not parallel to one another. The teeth of a beveloid gear are cut at an angle tothe axis of the gear, which allows the gear to mesh with another beveloid gear or a straight-tooth bevel gear. Beveloid gears can be either external or internal, dependingon whether the teeth are located on the outer or inner surface of the gear.

Advantages of Bevel oid Gears

Applications of Bevel oid Gears

Beveloid gears are used in a wide range of applications, including:

Conclusion

Bevel oid gears are a critical component of many mechanical power transmissionsystems. Their unique design provides several advantages over traditional straight-toothbevel gears, including improved load carrying capacity, reduced noise and vibration, greater design flexibility, and improved efficiency. With their broad range of applications and benefits, beveloid gears are an essential component of manymechanical systems that require precise and reliable power transmission.