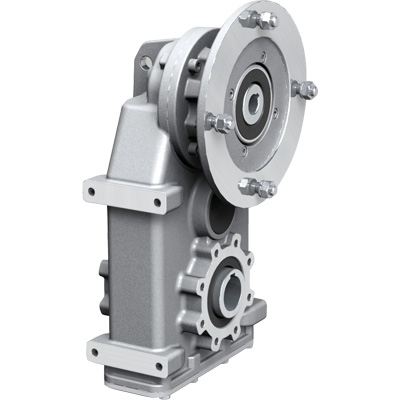

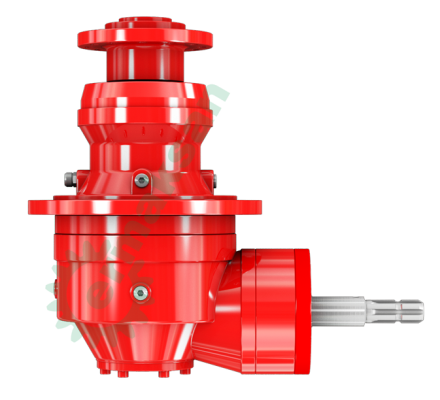

Shaft-Mounted Helical Gearboxes

Shaft-mounted helical gearboxes are a type of power transmission equipment that arecommonly used in various industrial applications. They are designed to transmit powerbetween a motor and a driven machine, allowing them to operate efficiently andeffectively. In this blog post, we will take a closer look at shaft-mounted helicalgearboxes, their functions, types, and benefits.

Functions of Shaft-Mounted Helical Gearboxes

The primary function of a shaft-mounted helical gearbox is to transmit power between a motor and a driven machine. This is achieved by using helical gears that mesh with eachother, allowing them to transmit power smoothly and efficiently. The gearbox is mounted directly onto the shaft of the driven machine, eliminating the need for a separate coupling or foundation.

Benefits of Shaft-Mounted Helical Gearboxes

Shaft-mounted helical gearboxes offer several benefits over other types of powertransmission equipment. Some of the most significant benefits of shaft-mounted helicalgearboxes include:

Types of Shaft-Mounted Helical Gearboxes

There are several different types of shaft-mounted helical gearboxes available on themarket, each designed for specific applications and operating conditions. Some of themost common types of shaft-mounted helical gearboxes include:

In conclusion, shaft-mounted helical gearboxes are an essential component in variousindustrial applications. They are designed to transmit power between a motor and a driven machine, allowing them to operate efficiently and effectively. By understandingthe functions, types, and benefits of shaft-mounted helical gearboxes, users can select theright type of gearbox for their specific application, ensuring maximum performance andefficiency.

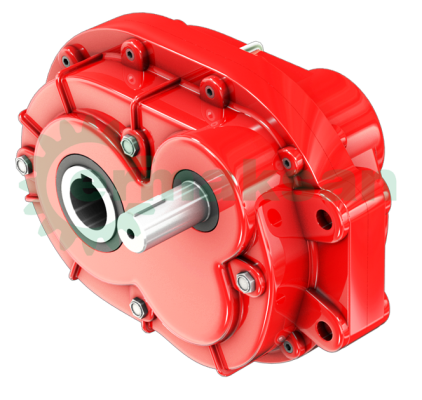

Rolling Mill Gearboxes

Rolling mill gearboxes play a vital role in the steel production process, as they help totransmit power and torque from the main motor to the rolling mill. These gearboxes arecritical components in the steel manufacturing process, and their reliability andperformance can have a significant impact on the overall production efficiency andprofitability of a steel mill.

In this blog post, we will take a closer look at rolling mill gearboxes, their functions, types, and maintenance practices.

Functions of Rolling Mill Gearboxes

The primary function of a rolling mill gearbox is to transmit power and torque from themain motor to the rolling mill. The gearbox also provides speed reduction and torquemultiplication, which helps to increase the force applied to the steel being rolled. Rolling mill gearboxes must be able to handle high torque and heavy loads, and they must be designed to withstand the harsh operating conditions of a steel mill.

Types of Rolling Mill Gearboxes

There are several different types of rolling mill gearboxes, each designed for specificapplications and operating conditions. Some of the most common types of rolling millgearboxes include:

Maintenance Practices for Rolling Mill Gearboxes

Proper maintenance is essential for ensuring the reliability and performance of rollingmill gearboxes. Some of the most important maintenance practices for rolling millgearboxes include:

In conclusion, rolling mill gearboxes are critical components in the steel manufacturingprocess. They play a vital role in transmitting power and torque from the main motor tothe rolling mill, and their reliability and performance can have a significant impact on the overall production efficiency and profitability of a steel mill. By understanding thefunctions, types, and maintenance practices of rolling mill gearboxes, steel mills can ensure that their gearboxes are operating at peak performance and reliability.

Reducer Conveyor Belts

In many industrial applications, conveyor belts play a crucial role in the efficient andsafe transportation of materials. However, conveyor belts can operate at high speeds, making it challenging to control the flow of materials in some cases. That’s wherereducer conveyor belts come in. In this blog post, we’ll explore the features and benefitsof reducer conveyor belts.

Features of Reducer Conveyor Belts

A reducer conveyor belt is designed with a specialized gearbox that reduces the speed of the conveyor belt while maintaining the same torque. The gearbox is typically mounteddirectly onto the drive pulley of the conveyor belt and works by converting the high-speed rotational motion of the motor or engine into a lower speed but higher torqueoutput.

The reducer conveyor belt consists of a series of gears and bearings that are designed towithstand high loads and work efficiently in harsh environments. The gears are typicallymade of high-strength materials such as hardened steel or cast iron to handle the hightorque loads generated by the conveyor belt.

Benefits of Reducer Conveyor Belts

There are several benefits to using a reducer conveyor belt in industrial applications. Some of these benefits include:

Conclusion

In conclusion, reducer conveyor belts play an important role in many industrialapplications by improving the safety, efficiency, and control of conveyor systems. Theirability to reduce the speed of the conveyor belt while maintaining the same torqueoutput provides many benefits, including increased safety, improved efficiency, bettercontrol, longer belt life, and customizability. If you’re looking to improve your conveyorsystem’s performance, a reducer conveyor belt may be the solution you need.

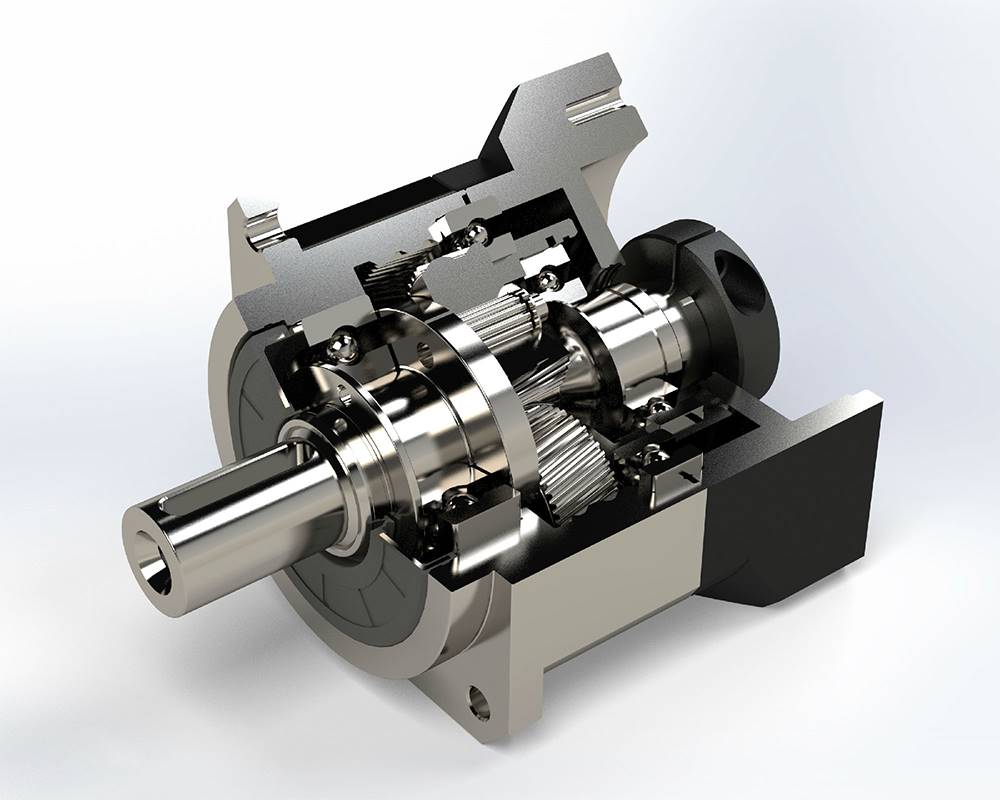

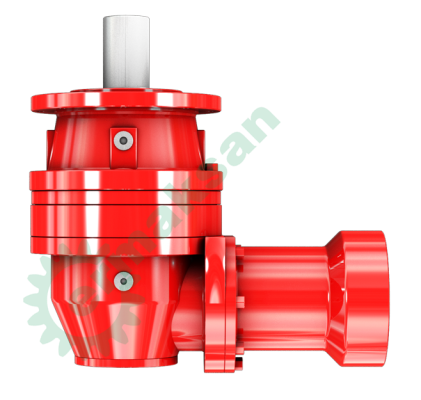

Planetary Gearheads

Planetary gearheads are an essential component in many mechanical systems, particularly those requiring high precision, torque, and speed control. These gearheadsare commonly used in industrial automation, robotics, medical equipment, and otherapplications that require precise motion control. In this blog post, we will take a closerlook at planetary gearheads, how they work, their advantages, and their applications.

How Planetary Gearheads Work:

Planetary gearheads work by using a system of gears that rotate around a central sun gear. The sun gear is typically connected to the motor, while the planet gears rotatearound it, driven by an outer ring gear. The configuration of these gears allows for a range of gear ratios, providing precise control over the speed and torque of the outputshaft.

Planetary gearheads are designed for high precision and accuracy, with minimal backlash and smooth operation. They are also able to handle high torque loads, makingthem ideal for applications where high torque is required at low speeds.

Advantages of Planetary Gearheads:

Planetary gearheads offer several advantages over other types of gearheads, including:

Applications of Planetary Gearheads:

Planetary gearheads are used in a wide variety of applications, including:

Conclusion:

Planetary gearheads are an essential component in many mechanical systems, providinghigh precision, torque, and speed control. They work by using a system of gears thatrotate around a central sun gear, providing a range of gear ratios for precise motioncontrol. Planetary gearheads offer several advantages over other types of gearheads, including high precision, high torque, compact size, low noise, and high efficiency. They are used in a wide variety of applications, including industrial automation, medicalequipment, aerospace, and automotive. With their ability to provide precise motioncontrol and handle high torque loads, planetary gearheads are a critical component in many mechanical systems.

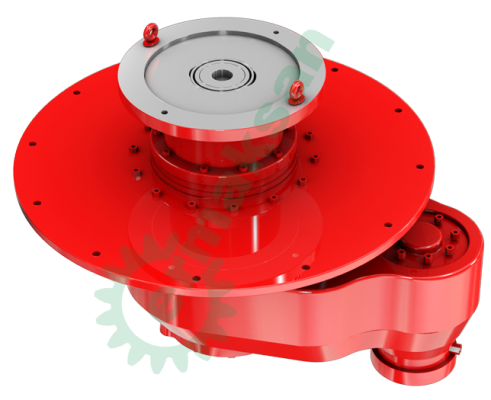

Pan Mixer Reducer

Pan mixer reducers, also known as pan mixer gearboxes, are a crucial component in theconstruction industry. They are designed to mix different types of constructionmaterials, including concrete, mortar, and plaster, to create a homogenous mixture thatcan be used for construction projects. In this blog post, we will take a closer look at panmixer reducers, their function, features, and benefits.

Function of Pan Mixer Reducers:

Pan mixer reducers are designed to mix different types of construction materials, ensuring a uniform and consistent mixture. They work by receiving power from an electric motor, which is transmitted to the gearbox. The gearbox then reduces the speedof the motor and increases the torque to mix the construction materials thoroughly.

Features of Pan Mixer Reducers:

Pan mixer reducers come with a range of features, including:

Benefits of Pan Mixer Reducers:

Pan mixer reducers offer several benefits to the construction industry, including:

Applications of Pan Mixer Reducers:

Pan mixer reducers are used in a variety of construction applications, including:

Conclusion:

Pan mixer reducers are a critical component in the construction industry, ensuring a uniform and consistent mixture of different construction materials. They offer severalbenefits, including improved mixing quality, increased efficiency, reduced labor costs, and greater flexibility. With their high-quality materials, compact design, andcustomization options, pan mixer reducers are an ideal solution for the constructionindustry. They are used in concrete mixing, mortar mixing, and plaster mixingapplications, ensuring that construction materials are of high quality and uniformconsistency.

Octopus Mixer Type Reducers

Octopus mixer type reducers are a type of gear reducer that is commonly used in industrial mixing applications. They are designed to provide high torque and low-speedoutput to mix materials in a precise and efficient manner. In this blog post, we’ll explorethe features and benefits of octopus mixer type reducers.

Features of Octopus Mixer Type Reducers

Octopus mixer type reducers consist of a gearbox with several shafts that are arrangedin a circular pattern, similar to the legs of an octopus. Each shaft is connected to a mixing blade, which rotates around the central axis of the gearbox.

The gearbox is typically made of high-strength materials such as cast iron or steel towithstand the high torque loads generated during the mixing process. The shafts andblades are also made of durable materials to handle the abrasive nature of many mixingapplications.

Octopus mixer type reducers are available in a range of sizes and torque capacities tomatch the requirements of the mixing application. They can also be customized toinclude additional features such as heating or cooling elements to maintain a consistenttemperature during the mixing process.

Benefits of Octopus Mixer Type Reducers

There are several benefits to using octopus mixer type reducers in industrial mixingapplications. Some of these benefits include:

Conclusion

In conclusion, octopus mixer type reducers are a versatile and reliable solution for manyindustrial mixing applications. Their high torque capacity, precise mixing capabilities, low speed output, durability, and customizability make them an ideal investment forbusinesses looking to improve their mixing processes. By using octopus mixer typereducers, businesses can increase their productivity and efficiency, while also improvingthe quality of their products.

Helical Gear Reducer

Helical gear reducers are a type of power transmission equipment that are commonlyused in various industrial applications, including manufacturing, material handling, andprocessing. These gear reducers are designed to reduce the speed and increase thetorque of a motor, allowing it to drive heavy loads with ease.

In this blog post, we will take a closer look at helical gear reducers, their functions, types, and benefits.

Functions of Helical Gear Reducers

The primary function of a helical gear reducer is to reduce the speed of a motor whileincreasing its torque. This is achieved by using helical gears that mesh with each other at an angle, allowing them to transmit power smoothly and efficiently. The output shaft of the reducer is typically slower but has a higher torque than the input shaft, allowing it todrive heavy loads with ease.

Types of Helical Gear Reducers

There are several different types of helical gear reducers available on the market, eachdesigned for specific applications and operating conditions. Some of the most commontypes of helical gear reducers include:

Benefits of Helical Gear Reducers

Helical gear reducers offer several benefits over other types of power transmissionequipment. Some of the most significant benefits of helical gear reducers include:

In conclusion, helical gear reducers are an essential component in various industrialapplications. They are designed to reduce the speed of a motor while increasing itstorque, allowing it to drive heavy loads with ease. By understanding the functions, types, and benefits of helical gear reducers, users can select the right type of reducer for theirspecific application, ensuring maximum performance and efficiency.

Feed Mixer Reducer

Feed mixer reducers, also known as feed mixer gearboxes, are a critical component in the animal feed industry. They are designed to mix different types of feed ingredients, including grains, vitamins, and minerals, to create a nutritious and well-balancedanimal feed. In this blog post, we will take a closer look at feed mixer reducers, theirfunction, features, and benefits.

Function of Feed Mixer Reducers:

Feed mixer reducers are designed to mix different types of animal feed ingredients, ensuring a uniform and consistent mixture. They work by receiving power from an electric motor, which is transmitted to the gearbox. The gearbox then reduces the speedof the motor and increases the torque to mix the feed ingredients thoroughly.

Features of Feed Mixer Reducers:

Feed mixer reducers come with a range of features, including:

Benefits of Feed Mixer Reducers:

Feed mixer reducers offer several benefits to the animal feed industry, including:

Applications of Feed Mixer Reducers:

Feed mixer reducers are used in a variety of animal feed applications, including:

Conclusion:

Feed mixer reducers are an essential component in the animal feed industry, ensuring a uniform and consistent mixture of different feed ingredients. They offer several benefits, including improved feed quality, increased efficiency, reduced labor costs, and greaterflexibility. With their high-quality materials, compact design, and customization options, feed mixer reducers are an ideal solution for the animal feed industry. They are used in poultry feed, livestock feed, and fish feed applications, ensuring that animals receive a nutritious and well-balanced diet.

Elbow Reducers

Elbow reducers, also known as elbow reducers or elbow transition fittings, are an essential component in many piping systems. They are designed to connect pipes of different sizes and directions, allowing for smooth and efficient fluid flow. In this blog post, we will take a closer look at elbow reducers, how they work, their advantages, andtheir applications.

How Elbow Reducers Work:

Elbow reducers work by connecting pipes of different sizes and directions, allowing forfluid to flow efficiently through the system. They consist of two sections: an elbowsection that changes the direction of the pipe and a reducer section that reduces thepipe’s diameter.

Elbow reducers are available in different angles, including 45 degrees and 90 degrees, allowing for greater flexibility in piping system design. The angle of the elbow sectiondetermines the direction of the pipe, while the reducer section reduces the pipe’sdiameter to accommodate the smaller pipe size.

Advantages of Elbow Reducers:

Elbow reducers offer several advantages over other types of fittings, including:

Applications of Elbow Reducers:

Elbow reducers are used in a wide variety of applications, including:

Conclusion:

Elbow reducers are an essential component in many piping systems, allowing for theefficient flow of fluids through pipes of different sizes and directions. They are easy toinstall, cost-effective, and durable, making them an ideal solution for a wide variety of applications. Elbow reducers are commonly used in HVAC systems, plumbing systems, chemical processing, and food and beverage processing, among other applications. Withtheir ability to connect pipes of different sizes and directions, elbow reducers play a critical role in ensuring the smooth and efficient operation of many piping systems.

Cooling Tower Gear Reducer

Cooling tower gear reducers are an essential component of cooling towers. They play a critical role in the efficient and effective operation of the tower, ensuring that it can coolwater efficiently while reducing energy consumption. In this blog post, we will take a closer look at cooling tower gear reducers, their functions, benefits, and types.

Functions of Cooling Tower Gear Reducers

The primary function of a cooling tower gear reducer is to drive the fan that pulls airthrough the cooling tower. This fan creates a flow of air that cools the water as it passesthrough the tower. The gear reducer is responsible for controlling the speed and torqueof the fan, ensuring that it operates efficiently and effectively.

Benefits of Cooling Tower Gear Reducers

Cooling tower gear reducers offer several benefits over other types of gear reducers. Some of the most significant benefits of cooling tower gear reducers include:

Types of Cooling Tower Gear Reducers

There are several different types of cooling tower gear reducers available on the market. Some of the most common types of cooling tower gear reducers include:

In conclusion, cooling tower gear reducers are a critical component of cooling towers. They are designed to drive the fan that pulls air through the tower, ensuring that it can cool water efficiently while reducing energy consumption. By understanding thefunctions, benefits, and types of cooling tower gear reducers, users can select the righttype of reducer for their specific application, ensuring maximum performance andefficiency.