Uses of Couplings and Backstops

Couplings and backstops are two important components used in mechanical powertransmission systems.

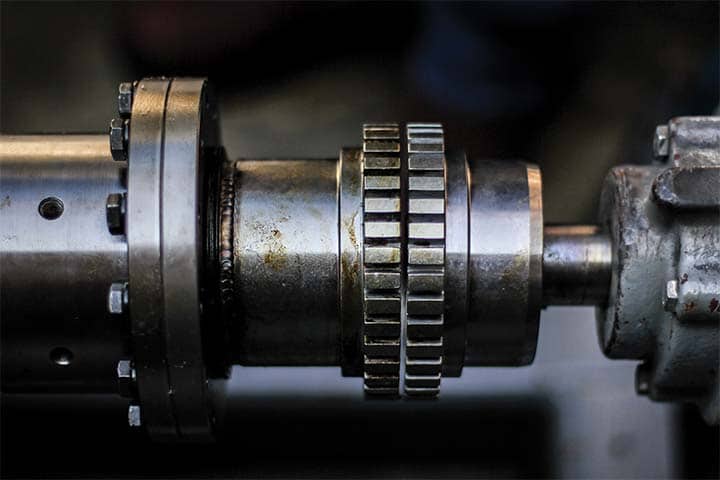

A coupling is a device used to connect two shafts together in order to transmit powerfrom one shaft to the other. Couplings are used to compensate for shaft misalignment, absorb shock and vibration, and protect machinery from overload. There are varioustypes of couplings including rigid couplings, flexible couplings, and fluid couplings. Rigid couplings are used when shaft alignment is accurate, while flexible couplings areused when there is a slight misalignment between the shafts. Fluid couplings are used tosmoothly transmit power between two shafts.

A backstop is a device used to prevent the reverse rotation of a machine or equipment. Itis typically used in conveyors, hoists, and other machinery that needs to maintain itsposition when the power is turned off. Backstops are installed between the gearbox andthe motor to prevent the gearbox from rotating backwards. There are various types of backstops, including sprag clutches, roller clutches, and ratchet and pawl mechanisms.

In summary, couplings are used to connect two shafts together to transmit power andcompensate for shaft misalignment, while backstops are used to prevent the reverserotation of a machine or equipment. Both couplings and backstops play important rolesin mechanical power transmission systems.