Planetary Gearheads

Planetary gearheads are an essential component in many mechanical systems, particularly those requiring high precision, torque, and speed control. These gearheadsare commonly used in industrial automation, robotics, medical equipment, and otherapplications that require precise motion control. In this blog post, we will take a closerlook at planetary gearheads, how they work, their advantages, and their applications.

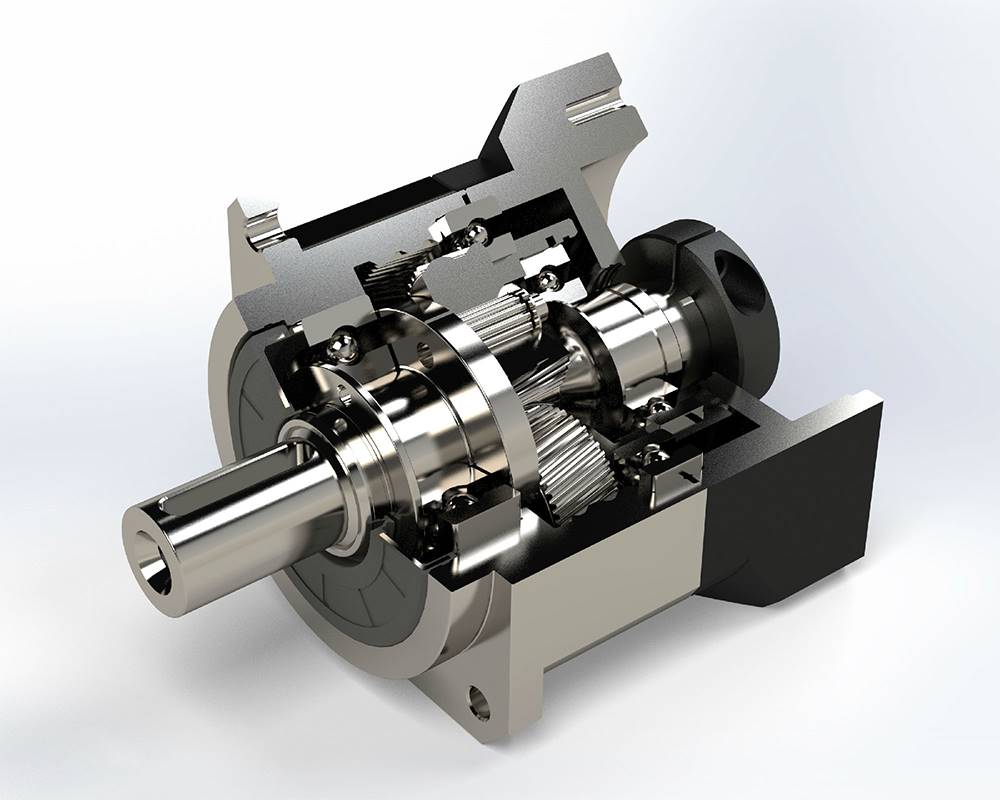

How Planetary Gearheads Work:

Planetary gearheads work by using a system of gears that rotate around a central sun gear. The sun gear is typically connected to the motor, while the planet gears rotatearound it, driven by an outer ring gear. The configuration of these gears allows for a range of gear ratios, providing precise control over the speed and torque of the outputshaft.

Planetary gearheads are designed for high precision and accuracy, with minimal backlash and smooth operation. They are also able to handle high torque loads, makingthem ideal for applications where high torque is required at low speeds.

Advantages of Planetary Gearheads:

Planetary gearheads offer several advantages over other types of gearheads, including:

Applications of Planetary Gearheads:

Planetary gearheads are used in a wide variety of applications, including:

Conclusion:

Planetary gearheads are an essential component in many mechanical systems, providinghigh precision, torque, and speed control. They work by using a system of gears thatrotate around a central sun gear, providing a range of gear ratios for precise motioncontrol. Planetary gearheads offer several advantages over other types of gearheads, including high precision, high torque, compact size, low noise, and high efficiency. They are used in a wide variety of applications, including industrial automation, medicalequipment, aerospace, and automotive. With their ability to provide precise motioncontrol and handle high torque loads, planetary gearheads are a critical component in many mechanical systems.