Octopus Mixer Type Reducers

Octopus mixer type reducers are a type of gear reducer that is commonly used in industrial mixing applications. They are designed to provide high torque and low-speedoutput to mix materials in a precise and efficient manner. In this blog post, we’ll explorethe features and benefits of octopus mixer type reducers.

Features of Octopus Mixer Type Reducers

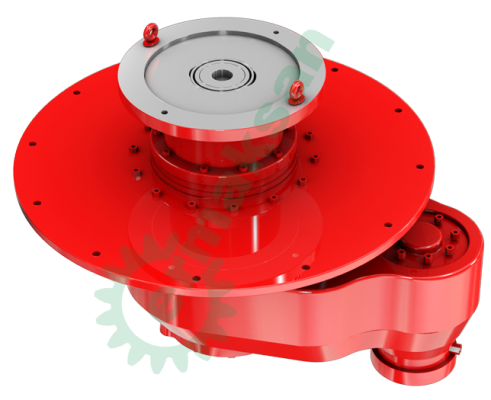

Octopus mixer type reducers consist of a gearbox with several shafts that are arrangedin a circular pattern, similar to the legs of an octopus. Each shaft is connected to a mixing blade, which rotates around the central axis of the gearbox.

The gearbox is typically made of high-strength materials such as cast iron or steel towithstand the high torque loads generated during the mixing process. The shafts andblades are also made of durable materials to handle the abrasive nature of many mixingapplications.

Octopus mixer type reducers are available in a range of sizes and torque capacities tomatch the requirements of the mixing application. They can also be customized toinclude additional features such as heating or cooling elements to maintain a consistenttemperature during the mixing process.

Benefits of Octopus Mixer Type Reducers

There are several benefits to using octopus mixer type reducers in industrial mixingapplications. Some of these benefits include:

Conclusion

In conclusion, octopus mixer type reducers are a versatile and reliable solution for manyindustrial mixing applications. Their high torque capacity, precise mixing capabilities, low speed output, durability, and customizability make them an ideal investment forbusinesses looking to improve their mixing processes. By using octopus mixer typereducers, businesses can increase their productivity and efficiency, while also improvingthe quality of their products.