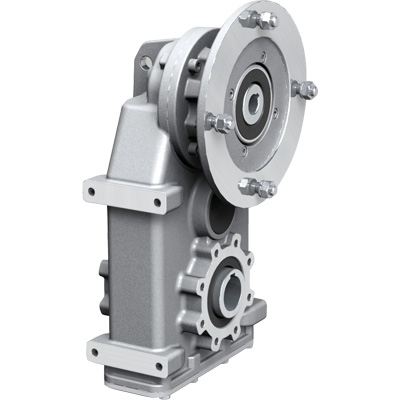

Shaft-Mounted Helical Gearboxes

Shaft-mounted helical gearboxes are a type of power transmission equipment that arecommonly used in various industrial applications. They are designed to transmit powerbetween a motor and a driven machine, allowing them to operate efficiently andeffectively. In this blog post, we will take a closer look at shaft-mounted helicalgearboxes, their functions, types, and benefits.

Functions of Shaft-Mounted Helical Gearboxes

The primary function of a shaft-mounted helical gearbox is to transmit power between a motor and a driven machine. This is achieved by using helical gears that mesh with eachother, allowing them to transmit power smoothly and efficiently. The gearbox is mounted directly onto the shaft of the driven machine, eliminating the need for a separate coupling or foundation.

Benefits of Shaft-Mounted Helical Gearboxes

Shaft-mounted helical gearboxes offer several benefits over other types of powertransmission equipment. Some of the most significant benefits of shaft-mounted helicalgearboxes include:

Types of Shaft-Mounted Helical Gearboxes

There are several different types of shaft-mounted helical gearboxes available on themarket, each designed for specific applications and operating conditions. Some of themost common types of shaft-mounted helical gearboxes include:

In conclusion, shaft-mounted helical gearboxes are an essential component in variousindustrial applications. They are designed to transmit power between a motor and a driven machine, allowing them to operate efficiently and effectively. By understandingthe functions, types, and benefits of shaft-mounted helical gearboxes, users can select theright type of gearbox for their specific application, ensuring maximum performance andefficiency.