Helical gear reducers are a type of power transmission equipment that are commonlyused in various industrial applications, including manufacturing, material handling, andprocessing. These gear reducers are designed to reduce the speed and increase thetorque of a motor, allowing it to drive heavy loads with ease.

In this blog post, we will take a closer look at helical gear reducers, their functions, types, and benefits.

Functions of Helical Gear Reducers

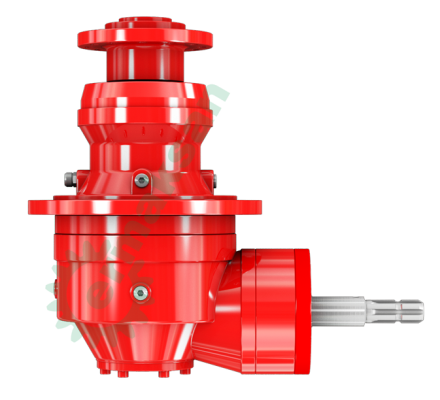

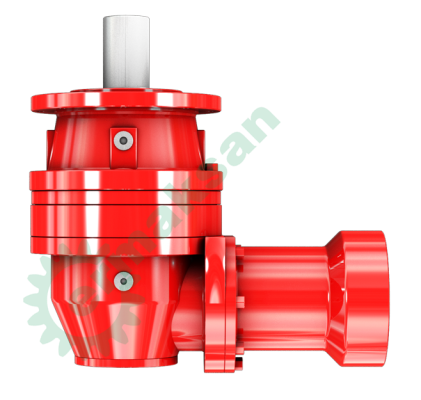

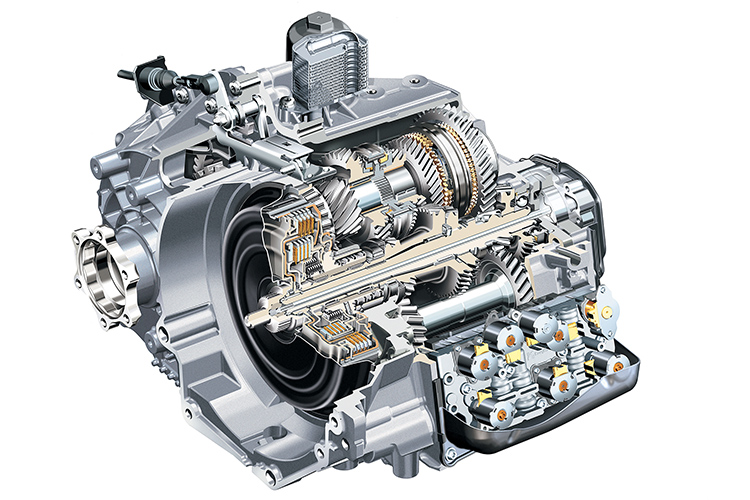

The primary function of a helical gear reducer is to reduce the speed of a motor whileincreasing its torque. This is achieved by using helical gears that mesh with each other at an angle, allowing them to transmit power smoothly and efficiently. The output shaft of the reducer is typically slower but has a higher torque than the input shaft, allowing it todrive heavy loads with ease.

Types of Helical Gear Reducers

There are several different types of helical gear reducers available on the market, eachdesigned for specific applications and operating conditions. Some of the most commontypes of helical gear reducers include:

Benefits of Helical Gear Reducers

Helical gear reducers offer several benefits over other types of power transmissionequipment. Some of the most significant benefits of helical gear reducers include:

In conclusion, helical gear reducers are an essential component in various industrialapplications. They are designed to reduce the speed of a motor while increasing itstorque, allowing it to drive heavy loads with ease. By understanding the functions, types, and benefits of helical gear reducers, users can select the right type of reducer for theirspecific application, ensuring maximum performance and efficiency.