Crowned gears are specialized gears that are used in applications where misalignmentbetween the driving and driven shafts is likely to occur. They are commonly used in equipment such as conveyors, printing presses, and packaging machinery, where precisealignment is crucial for optimal performance.

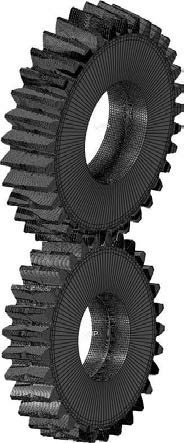

What are Crowned Gears?

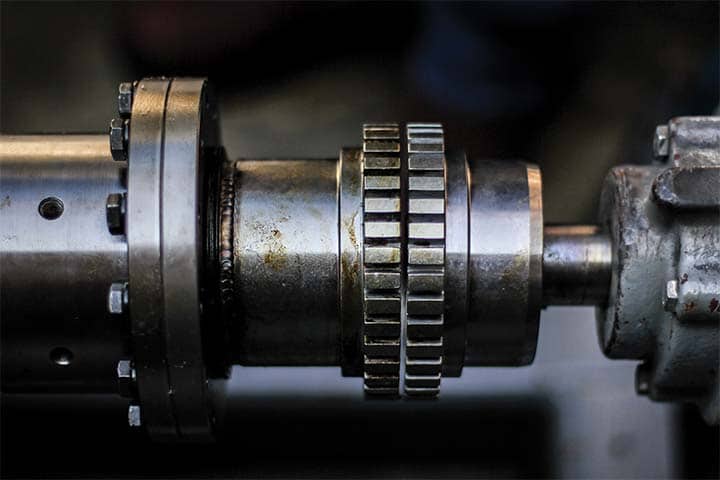

Crowned gears are gears that have a specially designed tooth profile that is slightlycurved or tapered towards the center of the gear. This design allows the gear toaccommodate small misalignments between the driving and driven shafts while stillmaintaining constant contact between the teeth of the gears. The slight curve or taper of the tooth profile ensures that the gears only touch at their highest point, which reduceswear and tear on the gear teeth and extends their lifespan.

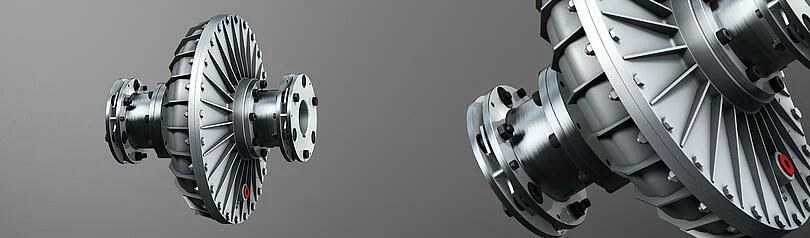

Applications of Crowned Gears

Crowned gears are commonly used in applications where precise alignment is difficult toachieve or maintain. They are particularly useful in equipment that is subject to changesin temperature, vibration, or other environmental factors that can cause misalignmentbetween the driving and driven shafts.

Some of the common applications of crowned gears include:

Benefits of Crowned Gears

The benefits of using crowned gears in equipment are numerous. Some of the keybenefits include:

In conclusion, crowned gears are a specialized type of gear that is designed toaccommodate misalignment between the driving and driven shafts. They are commonlyused in a wide range of industrial applications and can help to improve equipmentperformance, increase lifespan, and reduce downtime. By understanding the benefits of crowned gears, equipment operators can select the right type of gear for their specificapplication and ensure optimal performance and reliability.